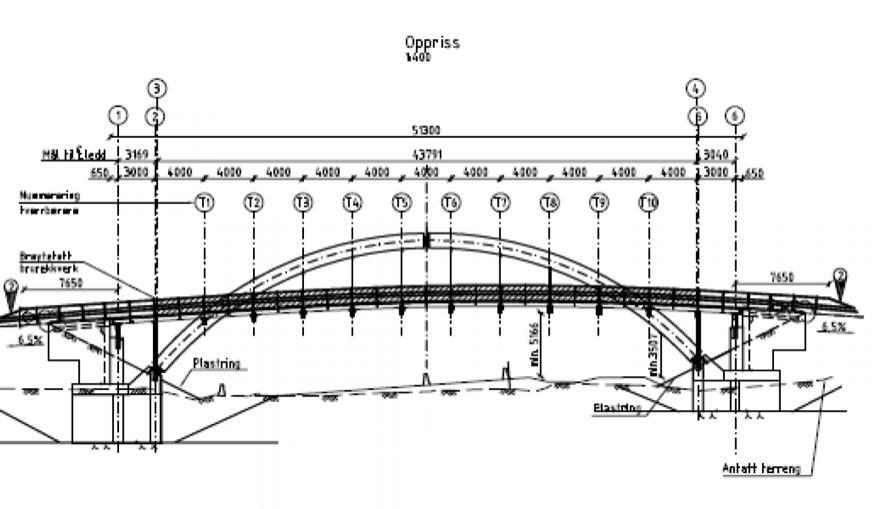

Vinsnes bridge, Norway

2015

Yabimo proudly undertook the execution of an innovative bridge construction project in Vinsnes. This endeavor highlights our commitment to quality engineering and advanced manufacturing techniques in delivering robust infrastructure solutions. The project scope encompassed the comprehensive production of essential bridge elements, including beams, bearings, and plates, which are critical for ensuring the structural integrity and longevity of the bridge.

Project Overview: The Vinsnes bridge project involved the design and production of various steel components tailored to meet the specific engineering requirements of the bridge. Our focus on durability, safety, and innovative design ensures that the bridge will serve the local community effectively for years to come.

Specifications and Technical Details:

- Total Weight of Steel: The project utilized a substantial quantity of steel, with a total weight of 55,640 kg, providing the necessary strength and durability required for a vital infrastructure component.

- Steel Grades:

- S355N: This structural steel grade constituted the bulk of the material used, weighing 54,715 kg. Known for its excellent weldability and high tensile strength, S355N is well-suited for demanding applications, making it an ideal choice for bridge construction.

- Weldox 700E / 690QL: A total of 925 kg of this high-strength structural steel was also used, offering enhanced toughness and resistance to extreme conditions, further contributing to the bridge’s resilience.

- Corrosion Protection: To ensure the longevity of the bridge components, we implemented various corrosion protection methods depending on the item:

- Hot Dip Galvanizing: This method provides a robust protective layer for steel elements, making them resistant to corrosion, particularly in harsh environmental conditions.

- Powder Coating: For components requiring aesthetic finish and extra protection, powder coating was applied, ensuring a durable, high-quality surface.

- Painting: Selected items received International-class paint, specifically formulated to withstand environmental stresses and prevent corrosion.

- Inspection and Certifications:

- Class Inspection: Item inspections were classified into categories 1 or 2, ensuring that all components met the requisite standards for safety and performance.

- Material Certificates: Depending on the item, we provided material certificates of class 3.1 or 3.2, which ensure traceability and compliance with international standards.

- Execution Class: The execution class for this project was designated as EXC3, indicating a higher level of complexity and strictness in quality control, ensuring that all manufacturing processes complied with the highest standards.

Manufacturing and Quality Assurance: Throughout the production phase, Yabimo emphasized rigorous quality assurance practices. Our engineering and quality control teams worked collaboratively to oversee the manufacturing processes, ensuring compliance with all specifications and standards. The use of advanced technologies and skilled craftsmanship in producing bridge elements reflects our dedication to excellence in infrastructure development.

Logistics and Delivery: Our logistics team coordinated the transportation of all bridge components to the construction site in Vinsnes, ensuring timely delivery while adhering to safety regulations. The assembly phase of the bridge was meticulously planned to facilitate efficient integration of all components.

Conclusion: The completion of the bridge project in Vinsnes not only underscores Yabimo’s expertise in steel construction but also contributes to enhancing local infrastructure and connectivity. This project stands as a testament to our commitment to delivering innovative, durable, and reliable construction solutions, ultimately serving the community’s needs for years to come.

Would you like to learn more about this and other projects?

Would you like to learn more about this and other projects?