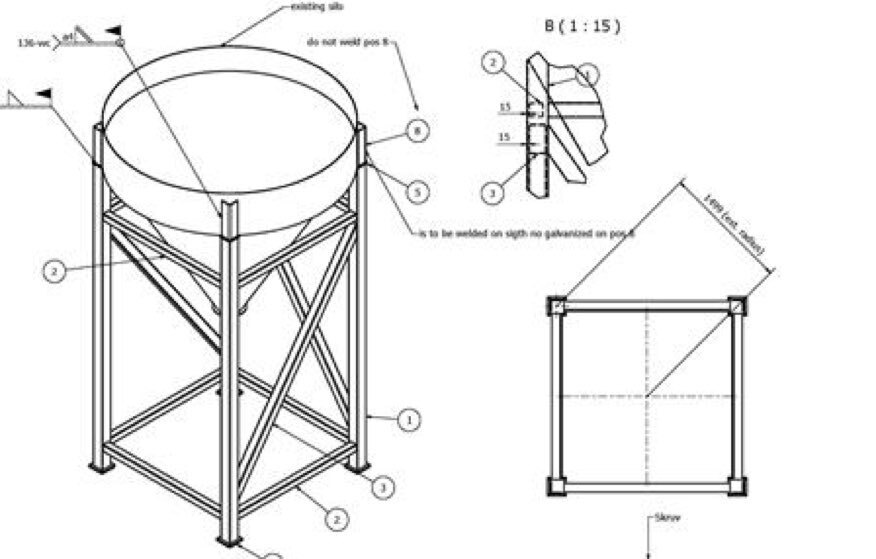

A supporting structure for the silo and slip-ups, Sweden

2013

The subject of the project was to produce the supporting structures for the silo and supporting structures for slip-ups. S355-quality steel used for load-bearing profiles and S235 for plates. The individual elements joined together by welds.

The design is protected against corrosion by blast cleaning to Sa2, 5, and painting with epoxy paint kit + polyurethane coating with a thickness of 160 microns. In addition, the supporting structure for the silo protected by hot dip galvanising. Control class EXC2 weld inspection.

Would you like to learn more about this and other projects?

Would you like to learn more about this and other projects?